Focus on industrial boiler water quality treatment is always an important step to enhance the production safety of industrial boilers as well as energy saving and environmental protection operational benefits. If the implementation of industrial boiler water quality treatment is not in place or the relevant equipment configuration is unreasonable, it is easy to induce the phenomenon of resource waste. In serious cases, it may lead to a series of production pollution and safety hazards.

For example, if the boiler water treatment operators for boiler water quality testing lack of standardized operation, then it is easy because of the wrong test results lead to boiler equipment corrosion or scaling problems, easy to affect the safe operation of boiler equipment effect. Once the above quality defects in the boiler, it is easy to cause adverse effects on the heat transfer properties of the boiler, and then lead to a decline in the thermal efficiency of the boiler and overheating of the heating surface and other risk problems.

In order to comprehensively enhance the safety, energy saving and environmental protection of industrial boiler operation efficiency, the management personnel for industrial boiler water treatment issues gradually increased the degree of attention. From an objective point of view, improve the industrial boiler water treatment capacity to a large extent can improve the boiler water treatment efficiency, reduce pollutant emissions, reduce the negative impact of boiler scaling and corrosion, while meeting the requirements of safety, energy saving and emission reduction.

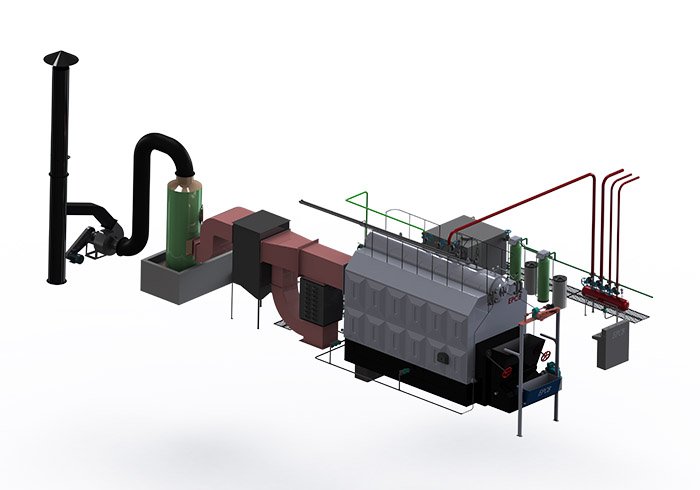

To this end, EPCB boiler analyzes the current situation of industrial boiler water treatment inspection and energy saving, dissects the common problems encountered in boiler water treatment inspection, and discusses industrial boiler water quality testing and energy saving methods.

Industrial Boiler Water Treatment Inspection and Energy Saving and Emission Reduction Analysis

One of the most common substances on earth, known as "the source of human life", water resources energy saving and emission reduction is an important link to achieve sustainable development of the green economy, and the status quo of energy saving and emission reduction of industrial boiler system water media treatment is not ideal, mainly in: high feed water impurities, high discharge rate, low recovery rate, low oxygen removal rate, water treatment The effective operation efficiency of the equipment is low, and the chemical cleaning liquid is discharged indiscriminately.

Combined with previous experience in water quality inspection, some industrial production enterprises in the boiler water treatment inspection does not pay attention to boiler water treatment, boiler water treatment management confusion, low efficiency of water treatment equipment, energy saving and emission reduction implementation effect is not strong and other issues.

For example, most of the current boiler water treatment equipment does not combine the actual situation of the water treatment method to make a reasonable choice, resulting in low efficiency and waste of water treatment resources more problems. In particular, some areas using underground when the water metal ion exceeds the standard problem is more prominent, in the absence of pretreatment measures will carry a large number of iron ions in the raw water pumped into the water treatment equipment, resulting in sodium ion resin rapid "poisoning" failure, and then lead to low efficiency in the operation of water treatment equipment, regeneration cycle is shortened, the waste of water resources and Chemical waste liquid discharge pollution and a series of problems.

Most of the micro and small enterprises are not configured according to the recommended requirements of special boiler water treatment operators, most of the boiler water medium treatment is only to cope with all kinds of inspection checks, did not solve the actual operation of the boiler medium is not up to standard, in the pot water treatment of the choice of chemicals, dosing control ratio, parameters monitoring mode and boiler water medium management system and other aspects of the scientific and rational approach is not conducive to the protection of boiler water The quality of the boiler water, and even cause heat loss and safety problems. In addition, the management does not have a reasonable recovery and scientific use of boiler condensate, hydrophobic, etc., which eventually leads to energy and water waste problems.

Inspection and Testing Practice of Industrial Boiler Water Treatment Analysis

1. Problems found in daily inspection

In order to eliminate the problem of scaling on the industrial boiler water treatment inspection effect brought negative impact, water treatment operators should pay more attention to the boiler scale, when the inspection found that the scale thickness of more than 1 mm or heating surface rust problems are relatively serious, or the boiler exhaust temperature suddenly becomes high or drop significantly, water treatment operators should immediately carry out descaling anti-corrosion work.

In combination with the type of boiler scale sample and the enterprise's own situation to reasonably choose the descaling method, chemical cleaning before the choice of boiler cleaning institutions with formal qualifications, and at the same time to have the corresponding supervision and inspection of qualified inspection agencies to submit the application for cleaning process supervision and inspection. If you choose boiler operation descaling, you should pay attention to strengthen the supervision of boiler water quality testing and increase the testing items appropriately to ensure the safe operation of the boiler to achieve the effect of descaling.

The problem of corrosion in industrial boilers can basically be regarded as a common quality defect problem during the operation of industrial boilers.

From the point of view of the cause, the occurrence of industrial boiler corrosion problems and boiler water dissolved oxygen, alkalinity, pH value regulation has a close relationship. Therefore, during the daily boiler water treatment operations, water treatment operators should strengthen the focus on boiler water dissolved oxygen, alkalinity, pH value regulation. When abnormalities are found, non-destructive testing and other activities should be carried out as soon as possible to avoid further spread of corrosion problems, resulting in boiler operation safety problems appear in the actual inspection found that the boiler water regulated with a variety of types of pharmaceuticals is more likely to meet the water quality standards for industrial boilers.

The use of the unit should be combined with the actual situation of the unit, clear job responsibilities, establish a sound water quality management system and strictly enforced to ensure that the quality of water quality meets the requirements, which is an important guarantee to enhance the effect of industrial boiler water treatment inspection. In the specific implementation process, water treatment operators should pay great attention to the conventional laboratory analysis link, the basic requirements of the test items hardness, alkalinity, pH value, according to the actual situation of the boiler to increase phosphate, dissolved oxygen and other items, when the quality of water vapor does not meet the standard requirements, should promptly find the reasons and treatment to pass.

2. Accident investigation analysis

While focusing on the problems encountered in the regular water media inspection of boilers, through the analysis of the causes of typical accident cases, summarize the lessons learned in the process of water treatment, can avoid the recurrence of similar accidents, improve the boiler water treatment operation and management capabilities to ensure the safe production of boilers.

In 2018, a gas boiler of a pharmaceutical company had a leaky accident in the furnace after the furnace was stopped, the boiler had obvious difficulties in steam and rising gas consumption for some time before the water seepage occurred, the maximum output of the boiler decreased, and the gas consumption increased by nearly 30% under the same evaporation, after the site investigation, the investigation of the water quality inspection report before the accident and the field scale sample test results showed that the water quality of the boiler was in long-term feed water hardness After the site investigation, the investigation of the water quality inspection report before the accident and the test results of the scale sample at the site showed that the water quality of the boiler was in the situation that the feed water hardness exceeded the standard and the pot water dosing was not enough.

Through the analysis of typical cases, boiler water treatment should be given sufficient attention and incorporated into the boiler safety operation management system; daily water quality testing and monitoring should play a guiding role in water quality regulation, and timely identify the causes and adjustments when not in line with the standard range; boiler scaling should be dealt with in a timely manner, after the analysis of scale samples using appropriate methods to remove scale.

3. Experimental Study

In the practice of water media inspection and testing there are still many issues that need to be further clarified and discussed, in order to find and solve many unknown details and boundary issues, there is a need to do a lot of basic experimental research, for the optimization of the inspection and testing method standards to provide theoretical support.

First of all, the boiler water agent adjustment amount of inquiry, most of the current industrial boiler pot water dosing are based on "empirical values" to determine, has not yet formed a widely applicable general method or standard to guide practice, is a major gap in the pot water treatment adjustment method.

To address the above issues, the distillation experiment can be conducted in three dimensions of hardness, agent, and test time to simulate the test, using high-density point data for curve fitting, and finally verified in the boiler, so as to suggest guidance for boiler agent regulation.

Secondly, in order to simulate the internal chemical reaction of the boiler, through the corrosion indicator piece of experiment, in the industrial boiler water quality standard value of the critical point of the corrosion degree of the test piece, respectively, in different acidity and alkalinity, different corrosion time under the working conditions, the corrosion amount and corrosion rate of the test piece of comparison test, corrosion rate curve, analysis of boiler water side corrosion related factors and their degree of influence, so as to boiler water medium test results and treatment advice to provide more powerful data support, can better grasp the boiler safety operation control range.

4. New Technology Research

At present, conventional detection means still exist in the complex detection steps, data accuracy is not high limitations, in order to improve the level of water medium detection capabilities, expand the scope of inspection and testing, the introduction of new technologies, new processes, new equipment as a solution.

The traditional weight method is cumbersome, time-consuming and inefficient for routine determination of dissolved solids and is rarely used today;

The solid conductivity ratio method is simple and fast to determine, but the solid conductivity ratio coefficient is not easy to accurately determine, often leading to a large error in the determination of the dissolved solids.

Now the use of intelligent drying constant weight automatic weighing system to measure dissolved solids, will significantly reduce the operation of cumbersome steps, while the method standard requirements of repeated constant weight can be solved, resulting in inefficiency and system errors, intelligent constant weight system can dry dozens of samples at the same time, can effectively improve the efficiency of detection and data accuracy.

As the technology of water treatment equipment continues to advance, the emphasis on water quality control in large enterprises is gradually increasing, which will place higher demands on the detection and analysis capabilities of trace elements. Compared with traditional inorganic analysis technology, ICP-MS technology has the advantages of lower detection limit, wider dynamic linear range, higher analytical precision and analytical speed, and can provide accurate isotope information. The use of this technology will further meet the requirements of enterprises for the precise regulation and control of water vapor quality, and provide strong support for the safety and technological deepening of special industrial equipment.

Suggestions For Energy Saving in Industrial Boiler Water Treatment

With the improvement of people's awareness of green development, minimize the various types of pollution generated in the process of water treatment, without or less use of chemicals has become an inevitable trend of industrial development. With the deepening of the strategy of sustainable development of water resources, as the largest proportion of water consumption of industrial production, how to properly and reasonably use water resources, improve the repeated utilization of water has become an urgent task of industrial water treatment work.

1. Correct choice of water treatment

The actual situation of each boiler use unit is very different, must be in accordance with the boiler use parameters and raw water quality, choose the most suitable for their own boiler water treatment method. This is particularly critical for the later water quality standards and reduce economic costs, but also to ensure that the boiler efficient and safe operation of the important premise.

For boiler parameters are low, the load is not high industrial boilers, such as rated evaporation ≤ 4.0 t / h and rated steam pressure ≤ 1.0 MPa boiler, when the feed water hardness is not greater than 4 mmol / L, the production process of steam quality requirements are not high, it is recommended that the use of simple pot water treatment, according to the characteristics of water quality to choose a single agent or a variety of mixed agents; for some production areas are more special For some production areas with high hardness water conditions, you can choose to add lime clarifier, mechanical filtration and other pre-treatment steps before softening treatment to reduce the magazine too much water into the resin softener to reduce its service life; using softening and pot dosing combined treatment of boilers, when other items meet the standard indicators, pot water dosing can be appropriately reduced so that the pot water alkalinity recommended to maintain a low value in the standard range.

2. Improve the professional capacity of water treatment operators

Boiler units should be configured with professional water treatment operators to supervise and manage the quality of boiler water vapor, the conditions of the unit should be regular professional technical training and guidance for water treatment operators to help operators improve the boiler water medium management, site pre-judgment, testing and inspection, emergency response, problem diagnosis and other comprehensive technical capabilities.

New green industrial transformation and development of professional water treatment operators continue to put forward higher requirements, water treatment technicians should not only meet the basic ability to adjust the boiler water quality indicators qualified, but also on this basis to energy saving and environmental protection as the goal to further reduce the boiler energy consumption and pollution of the environment. Strengthen the supervision of water treatment management, training more water treatment professionals and technical personnel, the reasonable use of scientific methods to solve problems is an important means to enhance the ability of water treatment management.

3. Water treatment system energy-saving management

Through the boiler water quality daily laboratory monitoring data and the characteristics of the pot of added pharmaceuticals, in the premise of water quality data can be properly reduced under the addition of phosphate pharmaceuticals to reduce the cost of chemicals, reduce industrial phosphate wastewater pollution hazards to environmental water bodies, to avoid improper addition of phosphate resulting in iron phosphate deposits on the boiler produced by the adverse effects.

How to strengthen the control management of discharge volume and frequency through the use of scientific and reasonable discharge methods has been an urgent problem for most boiler water treatment. In order to ensure that the water quality is up to standard and does not affect the steam quality under the condition of maximizing the utilization rate of pot water, we can try to combine the data of dissolved solids of pot water and the discharge rate data calculated from feed water and pot water chloride ion concentration as a reference, and adjust the discharge volume and frequency flexibly according to the specific operation of the boiler, so as to reduce the heat loss of the boiler and at the same time reduce the waste of water resources. If the discharge volume is large and the discharge frequency is high, it is recommended to equip the equipment such as discharge expansion device and heat exchanger, so as to effectively recover the heat energy contained in the sewage to achieve the purpose of energy saving and emission reduction.

As the best resource for boiler feedwater recycling, condensate can be recycled efficiently through the use of closed and open system types. However, it should be noted that although the open system is relatively simple and economical, the condensate should be recovered through a fine treatment device and tested before it is recycled to avoid introducing impurities into the system to cause safety hazards.

Conclusion

Boiler managers should continue to strengthen the importance of industrial boiler water media management as well as energy conservation and environmental protection. Enterprise managers as well as water treatment operators should be deeply aware of the importance of boiler water energy-saving treatment, and further strengthen the boiler water media management, testing and energy-saving work carried out in practice. If you have any questions about the use of boilers, welcome to contact EPCB Boiler.

EPCB Boiler, your personal boiler system experts!

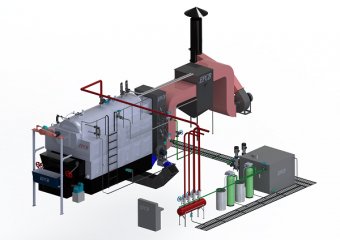

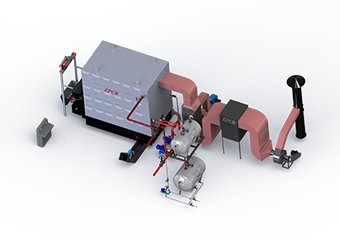

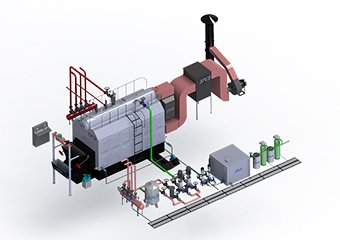

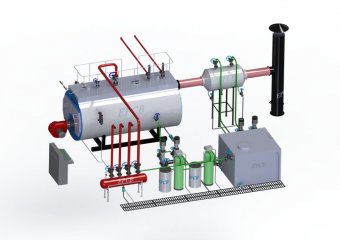

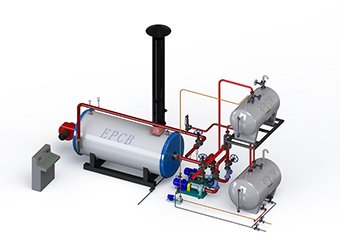

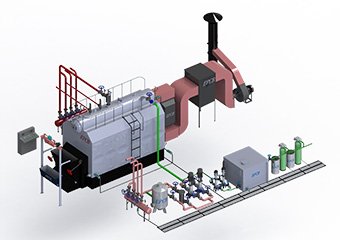

Steam Boiler

Steam Boiler Thermal Oil Boiler

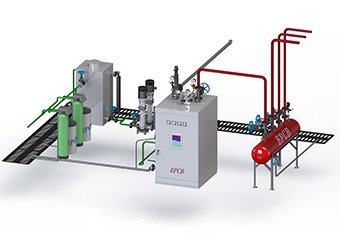

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

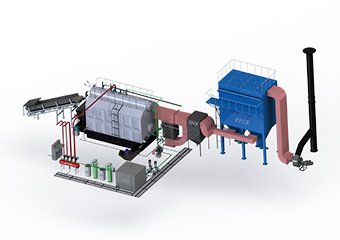

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

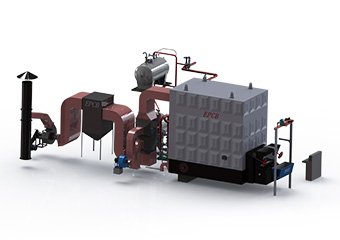

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler